2016-06-30

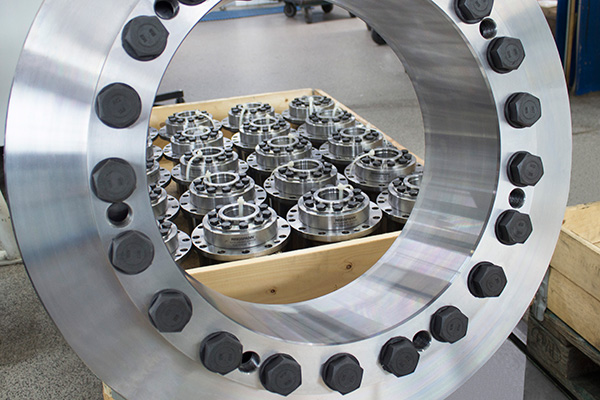

New shrink discs for large hollow shafts

RINGSPANN extends its range of frictional shaft-hub-connections

With a new 2016/17 product catalogue, manufacturer RINGSPANN is giving both design engineers and purchasers access to its extended total selection of shaft-hub-connections. The highlights of the extensive programme include new shrink discs for the external clamping of hollow shafts with large diameters of up to 620 mm, as well as delicate cone clamping elements for the internal clamping of shafts with very small diameters.

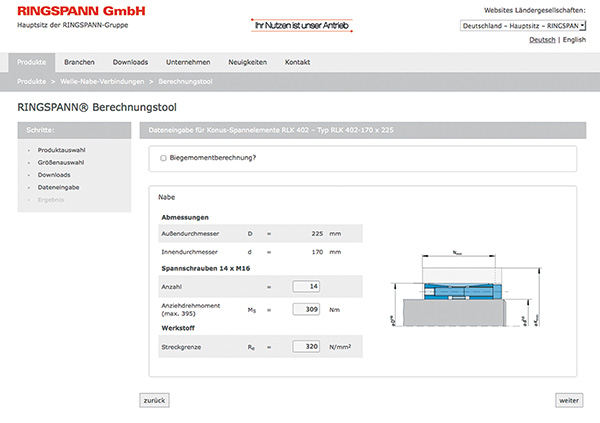

Bad Homburg, July 2016. – So that a motor shaft or a drive shaft can pass on its rotational force without any loss, it needs it a secure and firm connection to the hub or shaft of the moved machine element. For this purpose, manufacturer RINGSPANN produces a large range of frictional shaft-hub-connections which, depending on execution and version, transfer torques and axial forces as well as lateral forces and bending moments. The newly presented 2016/17 product catalogue now provides a complete overview of the current and extended portfolio of two and three-part shrink discs, cone clamping elements as well as star discs, special torque motor clamping systems and star spring washers for ball bearing compensation. On over 80 pages, all shaft-hub-connections are practically and very clearly described with colour images, technical drawings, data tables and short texts. In the catalogue, RINGSPANN also presents its innovative online calculation tool, which enables design engineers, product developers and purchasers to perform an individual and highly precise dimensioning of the optimal shaft-hub-connection.

Entering new dimensions

On the foundation of its close cooperation with drive technology research association "Forschungsvereinigung Antriebstechnik e.V. (FVA)" and strengthened by the successful integration of the South African Manufacturer Transmission Components Ltd. into the RINGSPANN group (2015), the company has considerably enhanced its market position as an international provider of shaft-hub-connections. This is also shown by the recent extensions to the product range. The outstanding new products include above all new shrink discs for the external clamping of hollow shafts with particularly large diameters, such as those increasingly required in wind power technology and the mining industry, in mining-related hoisting and conveying engineering and in power plant construction. The established series RLK 608 and RLK 603 among others have thus been extended to include two and three-part shrink discs for powerful shafts with diameters of up to 620 mm and 500 mm. These new shrink discs can transfer incredible torques of up to 4,225,000 Nm (RLK 608) or 1,460,000 Nm (RLK 603) and are suitable for the rigid no-play connection of hollow shaft gearboxes with machine shafts or of cardan shaft connection flanges with drive shafts.

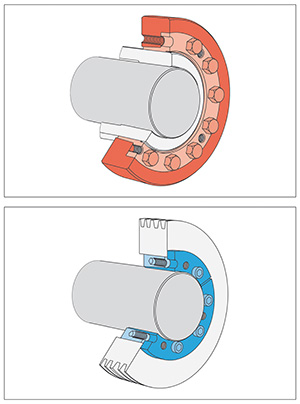

Torques and axial forces at the same time

All executions of the series RLK 608 are modern two-piece shrink discs (one stepped conical ring/one stepped conical bushing), which, owing to their closed construction, are insensitive to dirt and also ensure true running at high speeds. They can be simply and quickly mounted using clamping screws in a distance-controlled manner, without the need for a torque wrench. The RLK 603 shrink discs on the other hand follow the classic three-part setup (two stepped conical rings/one stepped conical bushing) and are mounted by means of a torque wrench. Both series make the simultaneous transmission of torques and axial forces possible and centre the hollow shaft or hub to the shaft. The design engineer can reliably and quickly carry out the exact application-specific or customer-specific dimensioning of the shrink disc using the online calculation tool from RINGSPANN.

For large and small diameters

While RINGSPANN primarily meets the increasing performance requirements of plant construction companies in wind power and mining-related technology with the new shrink discs for large hollow shafts, the manufacturer is responding, with its Trantorque Mini and Trantorque OE type shaft-hub-connections, to the requests of all those technical designers whose domain is the realisation of small and compact drives. In both cases, internal cone clamping elements are involved, which are characterised by an excellent concentricity. As well as torques and axial forces, they can also transfer bending moments. The Trantorque Mini series is suitable for tiny and thin shafts of just 3.0 to 16 mm in diameter and the Trantorque OE series is suited to shaft diameters of 17 to 35 mm.

RINGSPANN has continually expanded its range of frictional shaft-hub-connections over the last few years and constantly extended it to include new executions. The range currently consists of 25 different series with many hundreds of different variations, meaning that RINGSPANN can offer the right connection solution for almost any case of application. Looking at the versatility of its current selection of shrink discs, cone clamping elements, star discs, torque motor clamping systems and star spring washers, the company is now probably one of the leading manufacturers in this area of drive-related machine components. RINGSPANN frequently also acts in the area of shaft-hub-connections as an engineering partner for the development of customised special solutions.